Factory Supply Ir Proof - PSA/UV Resin Specific Heat Insulation Medium – Huzheng

Factory Supply Ir Proof - PSA/UV Resin Specific Heat Insulation Medium – Huzheng Detail:

Product Series

| No. | Code | Appearance | Solid content% | Haze of coating film% | VLT+IRR % | VLT % |

| 1 | CQ-81G16-TOL | Black blue liquid | 16 | 1.50 | VLT+IRR≥ 165 | 70 |

| 2 | 6JH-81L30-TOL | Black blue liquid | 30 | 0.5 | VLT+IRR≥ 169 | 70 |

| 3 | CQS-81G16-TOL | Black liquid | 15 | 0.75 | VLT+IRR≥ 145 | 50 |

Product Feature

Good versatility, good compatibility, can match with most PSA or UV resin;

High heat insulation rate, the blocking rate of UV and IR is over 99%;

A number of independent intellectual property rights support, small dosage, cost-effective;

Strong weather resistance, after QUV 5000h test, no performance degradation, no color change;

Safe and reliable, no toxic and hazardous substances such as halogen, heavy metal, etc.

Product Application

It can be used in PSA or UV resin, for window film such as building window film, automotive solar film, or other fields that has the requirement of infrared blocking.

Application Method

Note: Small sample test with resin is necessary before use.

Take using in PSA resin for example, the detailed application steps are as follows:

First step: Taking out the below material by weight ratio: GTO solution: diluting agent: PSA resin=1:4:4. Adjusting the GTO dosage according to the parameter requested (7490) with testing machine with 950nm.

Diluting agent: the mixing of EA:TOL =1:1

Second step: Mixing. Mix them one by one: adding GTO solution — adding diluting agent — stirring — adding PSA resin while stirring. Stirring for about 40min after adding PSA, and then filtering the mixture with 1um filter cloth.

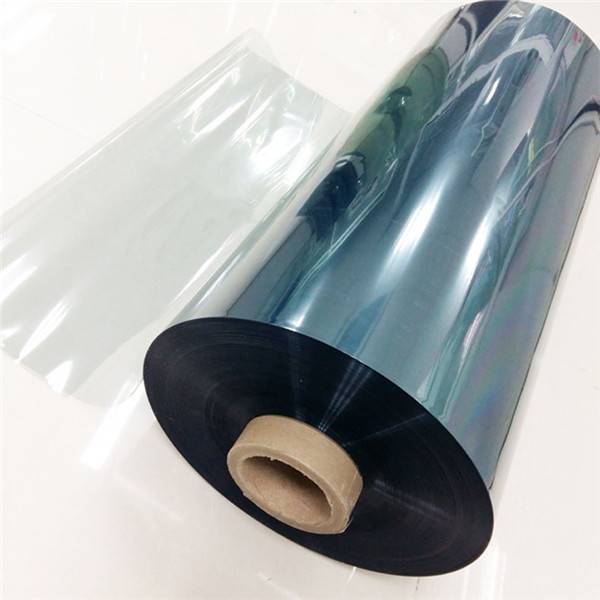

Third step: Choosing PET basic film. Choose the PET basic film with VLT over 90% and corona layer.

Fourth step: Coating. Coat them (the mixture in step 2) on the PET film by wet film coating machine.

Fifth step: Drying, laminating. Controlling the coating thickness between 6-8um, drying Temperature: 85~120 deg.

Package & Storage

Packing: 20 kgs/barrel.

Storage: in a cool, dry place, avoiding sun exposure.

Product detail pictures:

Related Product Guide:

Copper nanoparticle Highly effective antibacterial

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Factory Supply Ir Proof - PSA/UV Resin Specific Heat Insulation Medium – Huzheng , The product will supply to all over the world, such as: Suriname, South Africa, Bangladesh, To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!